1. Confirm the power supply voltage required by the machine and connect to the power supply.

2. Raw materials required for installation (generally plastic film roll and rope).

3. Place the coil device on the machine as required.

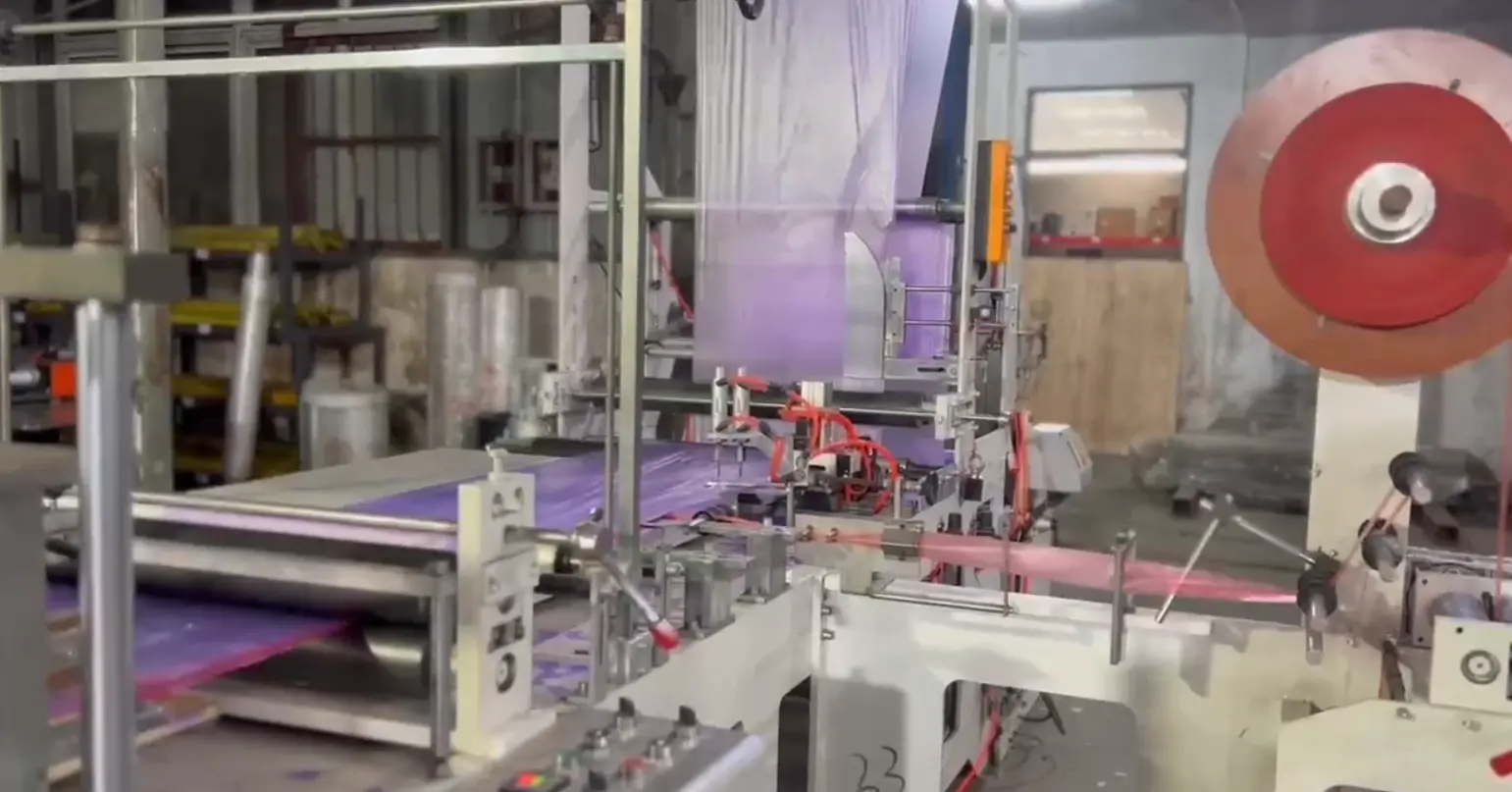

The machine can be used to pull rope garbage bags, draw rope and roll garbage bags, garbage bags, etc., all the processes are completed at one time.

simplicity of operator

Stable performance

High yield and low consumption

Bag making width | 60-500mm |

Bag making length | 450-600mm |

Bag making speed | 80-150 PCS/min |

Main technical parameters: | The whole machine is a 10mm steel plate body. |

Machine maincontroller | Single-channel PC box control |

Power of main motor | 1.5kw AC motor with 10 speed reducer |

Active feeding motor control | 0.75kw220v Huichuan frequency conversion control, linear potentiometer adjustment speed (analog quantity) |

Discharge downtime control | Panasonic, Japan, iv. v |

Passive feeding motor control | 0.75kw220v Huichuan frequency conversion control, Omron approach switch adjustment speed (switch volume) |

Fringe part: | |

Correction of deviation (before) | Type 250 Chongqing Enrui Si deviation correction machine |

Correction of deviation (after) | Type 700 Chongqing Enrui Si deviation correction machine |

Traction part: | |

Winding controller | PLC and supporting touch screen control, 24V power supply for Taiwan Mingyang switch power supply |

Winding motor power | 750w AC motor two |

Winding motor controller | Huichuan frequency conversion control,the Omron approach switch adjustment start-stop. |

Electrical configuration of the equipment: | |

Contact brand: Schneider | Intermediate relay brand: Schneider |

The power of the machine | About 12kw |

The weight of the machine | 3000kg |

Machine size | 10.5*2.5*1.75m (length * width * height) |

A cord bag machine is a device used to quickly make plastic bags or paper bags with cord seals. The use process is roughly as follows:

Prepare materials: Make sure you have the right material for the bag-making machine, which is usually plastic film or paper, choosing the right thickness and size as needed.

Loading materials: place the material roll on the material rack of the bag-making machine to ensure that the material is flat and wrinkle-free.

Adjust settings: adjust the cutting and sealing device of the bag machine according to the size of the required bag.

Start the machine: open the bag-making machine and let the machine preheat to the operating temperature.

Form the bag: The material passes through the rollers and molds of the bag maker to form the basic shape of the bag.

Seal and drawstring: Heat seal at the bottom of the bag to form a sealing strip. Then, the bag material on both sides of the bag is folded inward through the rope extraction mechanism, and fixed to the sealing strip to form a rope extraction opening.

Cutting and collecting: The bag is cut through the cutting device to form a single bag. The cut bag falls into the collection area or conveyor belt for subsequent processing.

Adjustment and maintenance: During use, regularly check and adjust the machine settings to ensure that the bag size and seal quality meet the requirements. At the same time, pay attention to the cleaning and maintenance of the machine to extend the service life.

When using the rope bag machine, attention should be paid to the safety operation procedures to avoid accidents such as pinching or scalding.

1. Confirm the power supply voltage required by the machine and connect to the power supply.

2. Raw materials required for installation (generally plastic film roll and rope).

3. Place the coil device on the machine as required.

1. Start the switch and enter the system page.

2. Click the "Start" button on the operating system page and wait for the initialization of the machine.

3. Confirm that there is no abnormal situation in the machine operation interface, and enter the operation steps.

1. Put the plastic film roll to be processed on the coil device and tighten it.

2. Adjust the opening and closing degree on the coil device, so that the plastic film has enough tension.

3. Insert the rope into the rope system and adjust the tension of the rope piercing system.

4. Set the parameters such as length, width and quantity of bag making, and click the "Start" button to start bag making.

5. Monitor the control bag process, and stop the machine immediately in case of any abnormal situation.

1. Do not use unqualified or nonconforming raw materials to make bags.

2. Pay attention to the display and alarm information of the machine operation interface, and stop for checking immediately in case of abnormal situation.

3. Clean and maintain the machinery and equipment regularly to ensure the normal use of the equipment.

This guide dives into operating a rope bag machine effectively. By understanding the proper use and implementing regular maintenance, you'll ensure smooth operation, maximize production efficiency, and extend the lifespan of your equipment.