- > Search By Functions

- > Co-Extrusion

- > Search By Material

- > Search By Machines

- > Search By Machines

- > Search By Machines

What are you looking for?

The principle of the garbage bag making machine mainly involves the following steps:

Material preparation: The machine wraps the plastic film inside, ready for the subsequent bagging process.

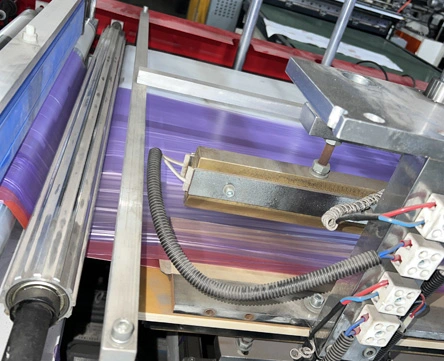

Conveying and flattening: The plastic film enters the machine through the conveying system and is flattened at a specific location to facilitate subsequent operation.

Add rope: Add plastic rope to the flattened plastic film and punch holes in the side mouth to form the pull outlet of the rope.

Sealing and cutting bag: After the heat sealing treatment of the sealing device, the sealing part of the bag is formed, and then the bag is cut into a single garbage bag by the cutting bag device.

Forming a bag: Due to the addition of the rope, the bag making machine also forms a bag while sealing, which is convenient for users to use.

Finish the bag: Finally, the user can pull the bag directly from the pull outlet of the rope and form a tie to prevent the garbage from leaking out.

In summary, the garbage bag making machine through a series of processes, including material preparation, conveying and flattening, adding rope, sealing and cutting the bag, forming the bag and completing the bag, and finally producing a garbage bag with rope.

Maximum width of finished bag (left and right width of bag) | 600mm |

Maximum depth of finished bag (mouth to bottom) | 650mm |

Maximum depth of finished bag (mouth to bottom) | 0.01mm-0.03mm |

Mechanical speed | 50—100pcs/min |

Cutting accuracy | ±0.5mm |

Complete power | 20KW |

Weight of the whole machine | 3000KG |

External size | 10400mm×1700mm×1800mm |